Characters

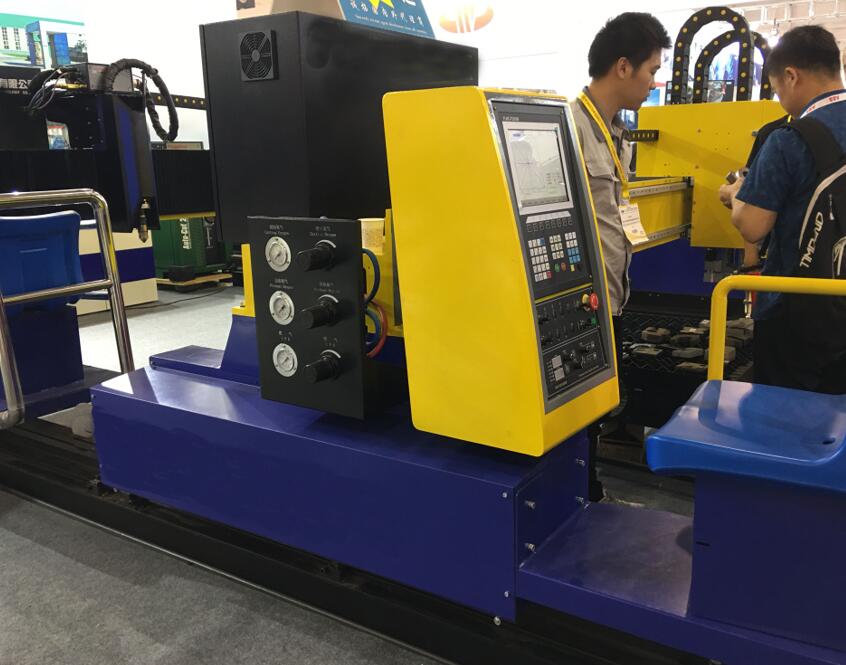

IDIKAR Bright series standard gantry cnc gas cutting machine designed for:

1. Gantry structure, Y, X axis with rigid synchronous belt drive axis with electric automatic lifting, to assure cutting speed and quality.

2. Dual drive, stable performance.

3. The set-up is very simple; all kinds of CAD graphics can be read directly by our system through U-disk. The software can be edict graphics automatically.

4. Collocated U disk interface and cutting code auto converting software for CAD drawing, CAD drawing can be input directly into the cutter through U-disk.

5. Tips for each operation is displayed at the screen at any moment, so operators can use our system without being trained or reading the instructions

6. Collocated indicator lights for various hitches. Hitch diagnosing is clear just at a glance and the maintenance is convenient and quick.

7. It is mainly applied in cutting heavy and middle metal steel.

8.24Kgs steel rail.

Application

Ship Building, Construction Equipment, Transport Equipment, Aerospace Industry, Bridge Building, military industrial, wind power, Structural Steel, Boiler containers, Agriculture Machinery, Chassis electrical cabinets, Elevator manufacturers, Textile Machinery, Environmental protection equipment,ect.

All kinds of metal materials such as steel, copper, aluminum and stainless steel can be processed. Applies to iron plate, aluminum plate, galvanized sheet, White Steel plate, Titanium plates, and so on like the sheet metal.

Parameter

|

Model

|

IDIKAR Bright-Series

|

|

Structure

|

Gantry structure

|

|

Input power

|

AC220V±10%50HZ

|

|

Cutting method

|

Plasma and Flame

|

|

Effective cutting range (mm)

|

4000x8000mm, 5000x8000mm, 6000x8000mm,

4000x10000mm, 5000x10000mm, 6000x10000mm,

(other size can be customized)

|

|

Plasma cutting thickness (mm)

|

0.1-30mm(Depends on the plasma source)

|

|

Flame cutting thickness(mm)

|

5-200mm

|

|

Motor and Deriver

|

Servo motor and driver, Dural driver.

|

|

Control system

|

FL-2300 CNC system, 10.inch Lcd display.

|

|

Height control

|

Auto THC for plasma

|

|

Rail

|

24Kgs steel rail

|

|

Nest software

|

FastCAM or StarCAM standard version

|

|

Files Transfer

|

USB Interface

|

|

Speed precision

|

≤±5%

|

|

Torch Height Control precision

|

≤±1.0mm

|

|

Longitudinal linear precision

|

±0.4mm/10m

|

|

Linear repeatable accuracy

|

±0.4mm/10m

|

Cutting Sample

Real factory

Real factory